Doctors rescue boys by propping open their airways using stents made via 3-D printing.The three infant boys were each near death. They were all on ventilators. All had airways so tiny that the breaths they tried to exhale couldn’t get out.

As a last-ditch effort to save their lives, doctors at the University of Michigan used a 3-D printer to produce small plastic stents that surgeons attached, just above the boys’ lungs, to prop the airways open.

In all three attempts, carried out since 2012, the procedure worked and the boys were able to breathe on their own. All three boys were able to go home—one for the first time.

In a first for 3-D printing of surgical implants, the stents were also designed to adapt as the boys grew from infancy to toddlerhood. An opening along one side of the rounded stents allowed their airways to double in size before the implants gradually dissolved, according to a report posted online on Wednesday inScience Translational Medicine by doctors at the University of Michigan.

The boys’ condition, known as tracheobronchomalacia, can be fatal but almost always resolves itself when children grow and their airways get bigger, at around age three.

In 2013, Glenn Green, an associate professor of otolaryngology at the University of Michigan, first reported using the “bioresorbable” airway splint in a infant, one of the three cases described on Wednesday. The first boy is doing well about three years after his surgery.

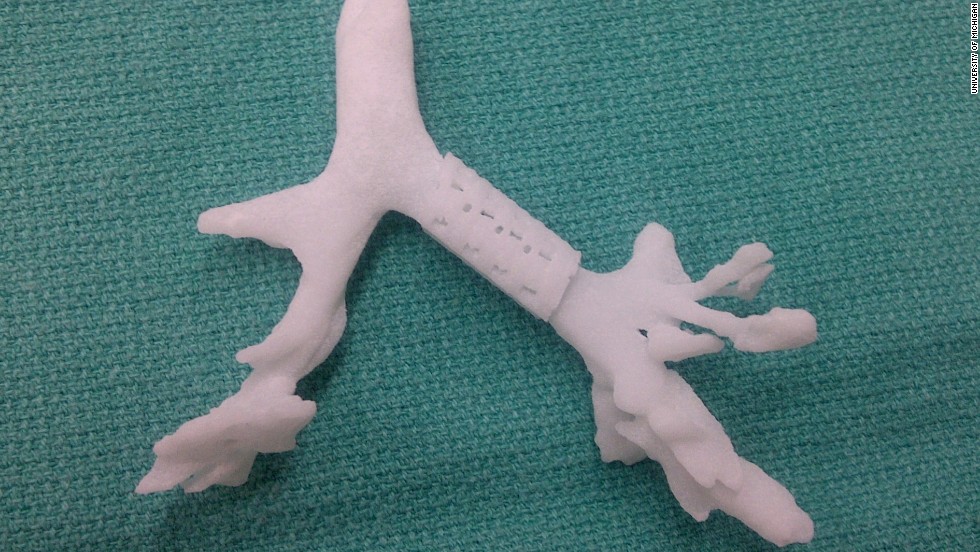

Green’s team printed out 3-D models of the boys’ tracheas and their bronchi, the Y-shaped branch taking air into the lungs, and then designed the stents to fit their precise anatomy. Each bronchus is only the size of a pencil lead in an infant, he says, but grows quickly.

According to the doctors, the implants were each designed and produced in less than five days.

Doctors also have started printing models to plan complex surgeries such as face transplants. Now that printed components allow new types of surgical procedures, Green sees 3-D printing as a dramatic advance. “I look at this as one of the biggest changes that is happening to surgery,” he says.

The airway stents were made from a polymer, polycaprolactone, and formed using a 3-D printing process called laser sintering. In that process, powdered material is laid down layer by layer and then fused with a laser, gradually producing a complex three-dimensional shape.

The stents are customized to match the length, diameter, and thickness of the child’s airway. The plastic material slowly dissolves over about three years, and as it breaks down it becomes less stiff, allowing the airway additional room to grow. Green says the plastic stent costs only about $10 in materials to produce.

Green says the experimental stents couldn’t be tested in animals because the boys’ condition doesn’t occur in animals. As a consequence, he had to obtain explicit permission each time from the U.S. Food and Drug Administration and negotiate with insurers to pay to transport the desperately ill children to Michigan. He said several children died while awaiting approval for the treatment. He’s hoping to get FDA approval and funding for a clinical trial so a more practical process for treating children with this condition can be developed.

http://www.technologyreview.com/news/537166/a-3-d-printed-implant-saves-lives/